Machine Control : The new benchmark in road surfacing

Engineering the future of UK road surfacing

- Improve surface smoothness and road quality

- Reduce costs with far improved material precision accuracy

- Minimise traffic disruption and improve safety for on-site staff

- Extend asset life while lowering long-term maintenance costs

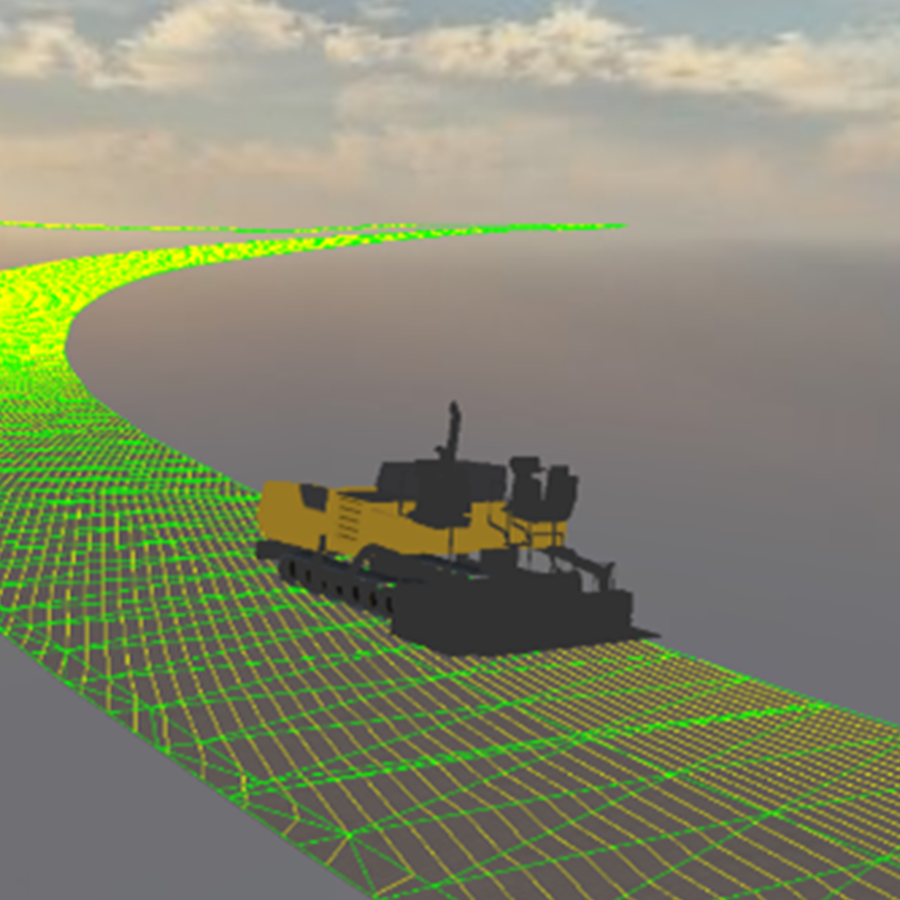

R3 Ltd’s Machine Control service brings racetrack-grade technology to UK road infrastructure—delivering smoother, longer-lasting surfaces at lower cost. By harnessing a fully digital workflow, Machine Control services from R3 Ltd set a new benchmark in road delivery, combining precision, speed and sustainability across every stage of resurfacing.

Trusted by contractors, councils and government bodies across the UK

Our Approach

Collect

High-speed LiDAR scanning captures surface data in live traffic—no full closures needed. We are machine-agnostic, with options to hire or buy machinery per project.

Optimise

We create precise 3D road models to optimise design for smoothness, drainage and accurate mill/fill calculations, and work collaboratively with your team to further refine and enhance the final design.

Execute

We work directly with your contractors to guide precision milling, reducing material use, waste, and errors, with on-site setup support provided as standard to help the contracting team until they’re confident using the system.

Verify

Get detailed post-project insights, including as-built 3D models, condition comparisons and IRI/heatmap analysis for measurable improvement.

Buy-in from the supply chain was crucial to the success of the project as this was the first time Machine Control technology was used in the country. The support and encouragement from Transport Scotland allowed us the opportunity to innovate. Collaborating with R3 and Topcon to shift away from traditional methods was a pleasure. The results, including an F1 racetrack-standard milled surface, showcase the project’s success. The improvement in IRI is clearly demonstrated in the data produced by the digital model.

Benefits

Reduced Costs

Efficient, data-driven milling with machine control enable pinpoint material accuracy reducing waste and personnel required to conduct manual surveys.

Superior Quality

Precision-controlled surfacing delivers smoother, more even road profiles, enhancing ride quality, improving IRI/RI scores and eliminating optical instrument errors.

Improved Safety

Automated survey and design processes reduce the need for on-site personnel, lowering exposure to live traffic and improving overall safety.

Extended Asset Lifespan

Smoother surfaces and reduced wear mean fewer potholes, repairs and interventions over time.

Insights for Future Planning

High-resolution data, digital twins, and integrated digital workflows enable smarter asset management, supporting BIM and As-Built documentation, maintenance forecasting and future upgrade planning.

Zero Survey Road Closures

High-speed LiDAR scanning captures data in live traffic conditions—no full closures required, minimising disruption to road users.

Reduced Environmental Impact

A smoother road profile and reduced rolling resistance lower fuel consumption and asphalt use, cutting material waste and unlocking major opportunities for measurable carbon savings by minimising over-milling and excessive asphalt application.

Shorter Project

Timescales

Digital workflows speed up surveys and eliminate setting out time ahead of milling, while precise milling delivers long-term time savings.

Case Study: A UK First on the A889

A UK-first deployment of machine control milling that:

- Delivered a 41% improvement in surface smoothness (IRI)

- Reduced material usage with predictions accurate to within 5%

- Enabled data capture in live traffic—with zero full closures

- Extended asset life, cut costs, and supported long-term sustainability

Why work with R3 Ltd?

Proven Expertise, Backed by Research

Our services are built on over 30 years of academic and applied research—translating deep technical knowledge into real-world impact.

Fast Mobilisation, Flexible Delivery

We respond quickly to project needs, offering adaptable commercial models that suit contractors, councils and asset owners alike.

Raising the Bar Across Roads, Runways & Racetracks

From national highways to F1 circuits, we’re setting new benchmarks for quality, efficiency, sustainability and innovation in surface delivery.

FAQs

How early in the project should we engage R3 Ltd for machine control services?

Ideally, as early as possible to maximise project benefits, but thanks to the simplicity of our service, we can deliver a project within just a few weeks if needed.

Do you operate the milling or paving equipment?

No. R3 Ltd supports surfacing and milling contractors by providing the digital models, machine control systems, and on-site setup/calibration—ensuring material is only removed or laid where needed.

Can I use R3 Ltd’s Machine Control service with my existing plant?

Yes. Our solution is machine-agnostic. Whether you’re hiring or purchasing, we ensure full compatibility with your site, plant, and project scope.

What types of projects benefit most from this technology?

Any road construction project can benefit, with slightly different approaches for resurfacing versus new builds.

- For resurfacing, we equip milling machines to deliver precision removal

- For new builds, we focus on getting it right from the start by equipping pavers

How does the service integrate with our existing design or survey data?

We take your existing design and optimise it, flagging any potential issues we identify. We can also use your existing survey data to verify and enhance the design as part of the process.

What happens if the road profile changes after initial scanning?

The initial scan provides a foundational reference for future condition monitoring, making it easier to identify changes such as subsidence or movement and accurately target future maintenance work.

How does the service handle drainage and water pooling issues?

Handling drainage is a key advantage of this technology over traditional methods. Drainage can be mapped and optimised in the digital environment before construction, allowing roads to be reprofiled with the correct cross-slopes, crowns and transitions for optimal water runoff.

Can we pilot the system on a smaller scheme before full rollout?

Yes — we can run a proof of concept on smaller projects or sections all the way up to full network rollouts.

How does this impact programme duration compared to traditional methods?

Overall, programme duration improves compared to traditional methods. Surveys are much quicker and safer through digital workflows, reducing on-site staff and traffic disruption. Setting out time ahead of milling is eliminated with direct digital transfer to milling machines. While milling itself may be slightly slower due to increased accuracy, end-to-end it takes less time to deliver a project whilst also providing superior surface quality and cost savings.

Contact Us